Contact Details

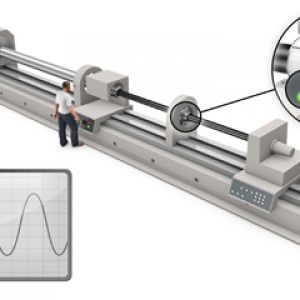

CoroCut QD, the reliable system from Sandvik Coromant for deep grooves and parting off with long overhangs, expands the offering of inserts and durable tools with over and under coolant. The system is supported with plug and play adaptors for easy handling and efficient coolant supply.

For bar feed manufacturers, process security in terms of good chip control and long reliable tool life is the key to an efficient production. To meet these needs CoroCut QD combines strong tools and inserts with rigid clamping and efficient coolant supply.

An important aspect for long tool life and few machine stoppages is good chip control. This is achieved by combining over and under coolant on all tools which keeps the temperature down at the cutting edge for less tool wear and a more stable performance, while at the same time providing for efficient chip evacuation.

Add to the support plug and play adaptors for easy coolant connection and a rigid, yet user-friendly clamping mechanism for easy insert changes, and you get CoroCut QD. This system not only ensures process security, but also easy handling for real machining efficiency.

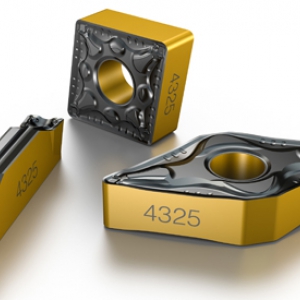

At the cutting edge, the cutting forces are high. To withstand this temperature, the tool material has high fatigue resistance and the tool tip seat features a backstop so the insert stays in its position preventing the seat from wearing down when the insert is indexed. Also the inserts themselves are developed with good coating adhesion and high edge-line security, for long tool life in every parting off operation.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- fatigue

fatigue

Phenomenon leading to fracture under repeated or fluctuating stresses having a maximum value less than the tensile strength of the material. Fatigue fractures are progressive, beginning as minute cracks that grow under the action of the fluctuating stress.

- fatigue resistance

fatigue resistance

Ability of a tool or component to be flexed repeatedly without cracking. Important for bandsaw-blade backing.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

PRODUCTS

PRODUCTS