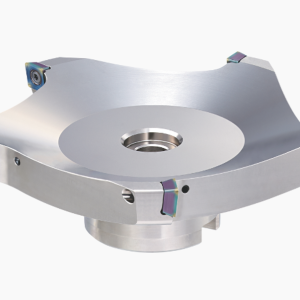

ElectroMill®: Precision Milling for Tough Bi-Metal & Interrupted Cuts

The flat machining of bi‐metal surfaces or milling applications involving an interrupted cut can present challenges to PCD or carbide milling cutters. Inserts may chip during the milling process, resulting in high machining costs & elevated levels of sub‐standard or rejected parts. ElectroMill® produces high quality, flat milled surfaces, even if an interrupted cut is present or multiple materials are to be machined simultaneously.