Contact Details

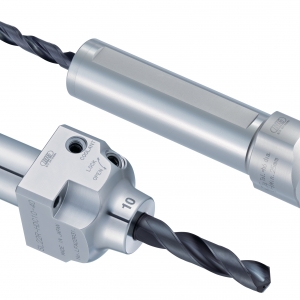

BIG Kaiser Precision Tooling is making dramatic improvements to BIG Profit Maker, KAISER and Unilock repair services at its Illinois facility. These include bringing certain services in-house that until recently had to be performed overseas, significant price reductions, eliminating charges for some commodity parts, and the addition of same-day services. Adjustments like these make it faster, more cost effective and easier to have mission-critical tooling repaired and maintained.

"Sending tools to us is much more convenient and cost effective for our customers," Shawn Stevens, Repair Technician, said. "For example, BIG Daishowa Profit Maker tools like Angle Heads—if the unit's crashed, broken, snapped or sheared off, we can fully fix it here now, and in one day if need be. You can pretty much tear the thing in half and it will be reparable. Plus, with the added cost-savings of our newly reduced repair costs, customers are spending less for the same service. Overall, it's a great improvement."

BIG Profit Maker Repair Improvements:

• Repair prices have been decreased an average of 40 percent to encourage customers to have repairs and periodic maintenance performed by a certified technician with the appropriate tooling

• No charge for commodity parts like cap screws, set screws and O-rings

• Same-day service available upon request

• Repairs are tested to assure runout accuracy, decibels and heat generation are within spec before being sent back to the customer

• Trade-in discounts and free inspection service of existing units are also available

KAISER Repair Improvements:

• Repairs to Series 310 EWN finish heads now done in the USA, whereas only Series 112 & 317 EWN finish heads were previously fixed here

• Typical KAISER repair can be done in less than one week Loaner heads are available during repair

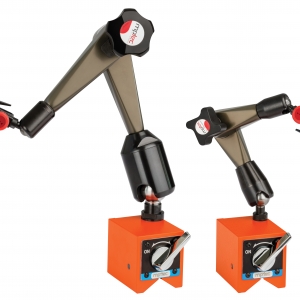

Unilock Repair Improvements:

• Until recently, Unilock repairs had to be sent back to Austria, but now most repairs can be done at the Illinois facility

• Repairs can be done in two days as long as the parts are available in stock

PRODUCTS

PRODUCTS