- Home

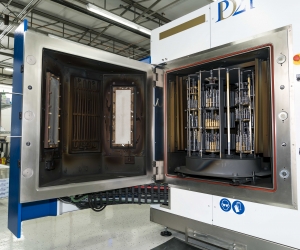

- Tool Coating/Treatment

- Cryogenic Tool Treatment Services

Cryogenic Tool Treatment Services

Zoller: Tool life monitoring

Robert Auer, an engineer and key account manager with Zoller, took a few minutes during IMTS 2010 to walk through the company's tool life monitoring and management system.

KOMET announces new partnership at IMTS 2014

KOMET Service North America, a partnership between KOMET of America and a variety of independent companies to service the KOMET brand of tools, welcomed Grinding Technology LLC to its list of partners at a special ceremony held during IMTS 2014. The Houston, Texas, company became the seventh partner to sign with KOMET Service since the launch of the service partnership at IMTS 2012.

Materials

Industry News for Materials

+ click to show 68 more results

Articles on Materials

+ click to show 128 more results

Author: Brett Reeder

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: CTE Staff

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: CTE Staff

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: CTE Staff

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Larry Adams

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Aaron Eller

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Ken Schnepf

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: John Saunders

Column: Shop Operations

Published:

Column: Shop Operations

Published:

Author: Ken Schnepf

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: David Conigliaro

Column: Get With The Program Column

Published:

Column: Get With The Program Column

Published:

Author: Brett Reynolds

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Robert Weinstein

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Patrick Waurzyniak

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Dr. Scott Smith

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Edmund Isakov, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Edmund Isakov, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeff Lantrip

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Edmund Isakov, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: John L. Johnson, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Dr. LaRoux K. Gillespie

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Daniel Margolis

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Daniel Margolis

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Prakash Mirchandani

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Van Niser

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jason Wells

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Greg Landgraf

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: David Novak

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Paul E. Augustus

Column: Feature Article

Published:

Column: Feature Article

Published:

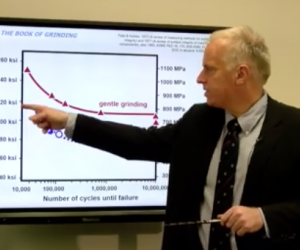

Author: Jeffrey A. Badger, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Charles M. Boyles

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Stephen A. Batzer

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jim Rowe

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Rich Dzierwa

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Michael Deren

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Charles M. Boyles

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Frank Mullett

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Bryson

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Charles M. Boyles

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Brad Lewis

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Brian Cline

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Tom Howes

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Kimberly R. Pontius

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Mike Castner

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Derek Phillips

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Joseph Halloran

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Norman Rohr

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Ronald Biagiotti

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Louis Caldarera Jr.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Andrew Johnson

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Changsheng Guo

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bernard North

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Cleveland

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: E. Gorzkowski

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Robert Weinstein

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Kip Hanson

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Kip Hanson

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Lead Angle Column

Published:

Column: Lead Angle Column

Published:

Author: Kip Hanson

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jim Wyant

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Michael C. Anderson

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Michael C. Anderson

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Michael C. Anderson

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: Michael C. Anderson

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Feature Article

Published:

Column: Feature Article

Published:

Videos on Materials

+ click to show 19 more results

Products for Materials

+ click to show 182 more results

Buyers Guide Companies for Materials

+ click to show 143 more results

Machining

Industry News for Machining

+ click to show 643 more results

Articles on Machining

+ click to show 2095 more results

Author: Dennis Spaeth

Column: Lead Angle Column

Published:

Column: Lead Angle Column

Published:

Author: EMUGE-FRANKEN USA

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: EMUGE-FRANKEN USA

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Author: CTE Staff

Column: Productive Times

Published:

Column: Productive Times

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Get With The Program Column

Published:

Column: Get With The Program Column

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author:

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Productive Times

Published:

Column: Productive Times

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Author:

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jim Hranica

Column: Get With The Program Column

Published:

Column: Get With The Program Column

Published:

Author: CTE Staff

Column: Productive Times

Published:

Column: Productive Times

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: Heidi Bethel

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Productive Times

Published:

Column: Productive Times

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author: Frank Burke

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Connor Benedict

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Productive Times

Published:

Column: Productive Times

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Brandt Taylor

Column: Manager's Desk Column

Published:

Column: Manager's Desk Column

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: CTE Staff

Column: Productive Times

Published:

Column: Productive Times

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Connor Benedict

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Connor Benedict

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author:

Column: Productive Times

Published:

Column: Productive Times

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Frank Burke

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jesse Trinque

Column: Get With The Program Column

Published:

Column: Get With The Program Column

Published:

Author: Jesse Trinque

Column: Get With The Program Column

Published:

Column: Get With The Program Column

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: CTE Staff

Column: Productive Times

Published:

Column: Productive Times

Published:

Author: CTE Staff

Column: Productive Times

Published:

Column: Productive Times

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Author: Yesenia Duran

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Yesenia Duran

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Get With The Program Column

Published:

Column: Get With The Program Column

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Augusto Naruse

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author: Brandt Taylor

Column: Machinist's Corner Column

Published:

Column: Machinist's Corner Column

Published:

Author: William Leventon

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Videos on Machining

+ click to show 630 more results

Products for Machining

+ click to show 2300 more results

Buyers Guide Companies for Machining

+ click to show 733 more results

Coatings

Industry News for Coatings

+ click to show 74 more results

Articles on Coatings

+ click to show 175 more results

Author: Brett Reeder

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: William Leventon

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: CTE Staff

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Christopher Tate

Column: Feature Article

Published:

Column: Feature Article

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: CTE Staff

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: CTE Staff

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Larry Adams

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Holly B. Martin

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Aaron Eller

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Ken Schnepf

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: John Saunders

Column: Shop Operations

Published:

Column: Shop Operations

Published:

Author: Ken Schnepf

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Robert Weinstein

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: David Conigliaro

Column: Get With The Program Column

Published:

Column: Get With The Program Column

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Del Williams

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Brett Reynolds

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Robert Weinstein

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Author: Patrick Waurzyniak

Column: Feature Article

Published:

Column: Feature Article

Published:

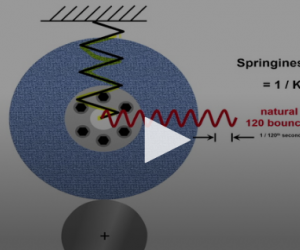

Author: Dr. Scott Smith

Column: Machine Technology Column

Published:

Column: Machine Technology Column

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Edmund Isakov, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeff Lantrip

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Edmund Isakov, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jim Haag

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Joseph Hazelton

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Edmund Isakov, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: John L. Johnson, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Fred Teeter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Dr. LaRoux K. Gillespie

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Daniel Margolis

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: CTE Staff

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Daniel Margolis

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Prakash Mirchandani

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Van Niser

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Susan Woods

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jason Wells

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Greg Landgraf

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: David Novak

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Paul E. Augustus

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Mark Olbrantz

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jeffrey A. Badger, Ph.D.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Roger Bollier

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Fred Teeter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Rich Dzierwa

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Charles M. Boyles

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Stephen A. Batzer

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Jim Rowe

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Kennedy

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Rich Dzierwa

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Michael Deren

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Charles M. Boyles

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Peter Fretty

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Bill Bryson

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Charles M. Boyles

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Brad Lewis

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Alan Richter

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Brian Cline

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Frank Mullett

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Tom Howes

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Kimberly R. Pontius

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Stanley Biernat Jr.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Roy Gat

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Mike Castner

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Derek Phillips

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Joseph Halloran

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Norman Rohr

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Ronald Biagiotti

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Louis Caldarera Jr.

Column: Feature Article

Published:

Column: Feature Article

Published:

Author: Andrew Johnson

Column: Feature Article

Published:

Column: Feature Article

Published:

Videos on Coatings

+ click to show 26 more results

Products for Coatings

+ click to show 81 more results

Buyers Guide Companies for Coatings

+ click to show 60 more results

Contact Details

Contact Details

Pagination

© Copyright 1995 - 2024. Cutting Tool Engineering. All rights reserved.