- Home

- Cooling/Lubricating

- Coolant

Coolant

Evaluating coolants

A coolant supplier having trouble getting customers to try a new product turned to Dr. Jeffrey Badger, the host of Cutting Tool Engineering's Grinding Doc Video Series, for some insight into how the supplier could convince shops to change coolant.

Tool-Flo booth visit at IMTS 2014

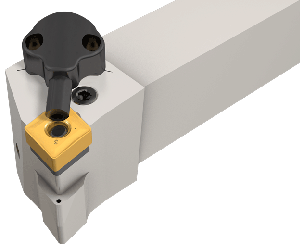

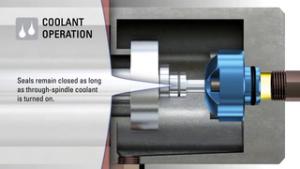

Tool-Flo Manufacturing Inc. featured coolant-fed clamps designed to eliminate the need to change or modify the toolholder at the company's booth during IMTS 2014. The holder connects to an existing coolant pump on a manual lathe. End users replace the current top clamp with the coolant-fed clamp to provide a direct coolant feed to the cutting edge.

Coolant strategy

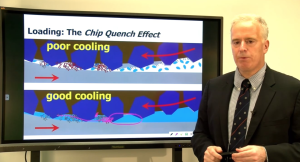

How close do you need to get the coolant nozzle to the grinding wheel? Dr. Jeffrey Badger offers some direction.

About the Grinding Doc Video Series: Thanks to his work as an independent grinding consultant and the author of the "Ask the Grinding Doc" column in Cutting Tool Engineering magazine, Dr. Jeffrey Badger routinely receives questions about grinding from shops all over the world. Through the magazine column and this video series, he provides shops with the insight and guidance they seek.

Green Metalworking Technologies, Part 2

Ron Sattler of Chemetall Inc. presents a Fast Track Seminar at the Cutting Tool Engineering booth during IMTS 2010. His presentation, titled "The Application of Sustainability in Metalworking Processes," is divided into two parts. Presented here is part two. View part one here.

Green Metalworking Technologies, Part 1

Ron Sattler of Chemetall Inc. presents a Fast Track Seminar at the Cutting Tool Engineering booth during IMTS 2010. His presentation, titled "The Application of Sustainability in Metalworking Processes," is divided into two parts. Presented here is part one. View part two here.

Coolant

Industry News for Coolant

Articles on Coolant

Column: Productive Times

Published:

Column: Feature Article

Published:

Column: Look Ahead Department

Published:

Column: Productive Times

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Shop Operations

Published:

Column: Ask the Grinding Doc Column

Published:

Column: Look Ahead Department

Published:

Column: Feature Article

Published:

Column: Ask the Grinding Doc Column

Published:

Column: Ask the Grinding Doc Column

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Productive Times

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Productive Times

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Machine Technology Column

Published:

Column: Feature Article

Published:

Column: Machine Technology Column

Published:

Column: Feature Article

Published:

Column: Productive Times

Published:

Column: Productive Times

Published:

Column: Productive Times

Published:

Column: Feature Article

Published:

Column: Look Ahead Department

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Productive Times

Published:

Column: Feature Article

Published:

Column: Look Ahead Department

Published:

Column: Productive Times

Published:

Column: Look Ahead Department

Published:

Column: Feature Article

Published:

Column: Look Ahead Department

Published:

Column: Look Ahead Department

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Column: Look Ahead Department

Published:

Column: Feature Article

Published:

Column: Feature Article

Published:

Videos on Coolant

Products for Coolant

Buyers Guide Companies for Coolant

Pagination

Sponsored Content

© Copyright 1995 - 2025. Cutting Tool Engineering. All rights reserved.