| 2L inc. |

978-567-8867 |

http://www.2linc.com |

| 2L inc. |

978-567-8867 |

http://www.2linc.com |

| 2L inc. |

978-567-8867 |

http://www.2linc.com |

| 2L inc. |

978-567-8867 |

http://www.2linc.com |

| 2L inc. |

978-567-8867 |

http://www.2linc.com |

| 3M Personal Safety Div. |

|

https://www.3m.com/3M/en_US/safety-us/ |

| 3M Personal Safety Div. |

|

https://www.3m.com/3M/en_US/safety-us/ |

| 3M Personal Safety Div. |

|

https://www.3m.com/3M/en_US/safety-us/ |

| 3M Personal Safety Div. |

|

https://www.3m.com/3M/en_US/safety-us/ |

| A. Landau Diamond Tool & Wheel Co. |

215-675-2700 |

http://www.alandau.net |

| A. Landau Diamond Tool & Wheel Co. |

215-675-2700 |

http://www.alandau.net |

| A.A. Jansson Inc. |

248-674-4811 |

http://www.aajansson.com |

| A.G. Davis/AA Gage |

586-977-9000 |

http://www.agdavis-aagage.com |

| Abrasive Technology |

740-548-4100 |

http://www.abrasive-tech.com |

| Abrasive Technology |

740-548-4100 |

http://www.abrasive-tech.com |

| Abrasive Technology |

740-548-4100 |

http://www.abrasive-tech.com |

| Accu-Cut Diamond Tool |

708-457-8800 |

http://www.accucutdiamond.com |

| Accu-Cut Diamond Tool |

708-457-8800 |

http://www.accucutdiamond.com |

| Adams Supply Co. |

714-754-0551 |

http://www.ymwtaps.com |

| Advanced Diamond Products LLC |

908-850-8505 |

http://www.advanceddiamondproducts.com |

| Advanced Diamond Products LLC |

908-850-8505 |

http://www.advanceddiamondproducts.com |

| Advanced Diamond Products LLC |

908-850-8505 |

http://www.advanceddiamondproducts.com |

| Advanced Diamond Products LLC |

908-850-8505 |

http://www.advanceddiamondproducts.com |

| Advanced Diamond Products LLC |

908-850-8505 |

http://www.advanceddiamondproducts.com |

| Advanced Diamond Products LLC |

908-850-8505 |

http://www.advanceddiamondproducts.com |

| Advanced Machine & Engineering |

815-979-3380 |

http://www.ame.com |

| Advanced Superabrasives |

702-564-7735 |

http://www.advanced-sa.com |

| Advanced Superabrasives |

702-564-7735 |

http://www.advanced-sa.com |

| Advanced Tool Inc. |

315-768-8502 |

http://www.endmillsolutions.com |

| Advent Tool & Mfg. Inc. |

800-THREAD-4 |

http://www.advent-threadmill.com |

| Advent Tool & Mfg. Inc. |

800-THREAD-4 |

http://www.advent-threadmill.com |

| Advent Tool & Mfg. Inc. |

800-THREAD-4 |

http://www.advent-threadmill.com |

| Advent Tool & Mfg. Inc. |

800-THREAD-4 |

http://www.advent-threadmill.com |

| Advent Tool & Mfg. Inc. |

800-THREAD-4 |

http://www.advent-threadmill.com |

| AHD/Flex-E-On Inc. |

330-928-4456 |

http://www.ahd-flex-e-on.com |

| Alfra Tools LLC |

847-844-8900 |

http://www.alfratools.com |

| Allen Benjamin Corp. |

480-968-7937 |

https://www.allenbenjamin.com/ |

| Allied Machine & Engineering |

330-343-4283 |

http://www.alliedmachine.com |

| Allied Machine & Engineering |

330-343-4283 |

http://www.alliedmachine.com |

| Allied Machine & Engineering |

330-343-4283 |

http://www.alliedmachine.com |

| Allied Machine & Engineering |

330-343-4283 |

http://www.alliedmachine.com |

| Allied Machine & Engineering |

330-343-4283 |

http://www.alliedmachine.com |

| Allied Machine & Engineering |

330-343-4283 |

http://www.alliedmachine.com |

| Allied Machine & Engineering |

330-343-4283 |

http://www.alliedmachine.com |

| Allied Machine & Engineering |

330-343-4283 |

http://www.alliedmachine.com |

| Allied Machine & Engineering |

330-343-4283 |

http://www.alliedmachine.com |

| Allied Tool Products |

414-355-8280 |

http://www.atptools.com |

| Allied Tool Products |

414-355-8280 |

http://www.atptools.com |

| Allied Tool Products |

414-355-8280 |

http://www.atptools.com |

| Allied Tool Products |

414-355-8280 |

http://www.atptools.com |

| Aloris Tool Technology Co. Inc. |

973-772-1201 |

http://www.aloris.com |

| Aloris Tool Technology Co. Inc. |

973-772-1201 |

http://www.aloris.com |

| Aloris Tool Technology Co. Inc. |

973-772-1201 |

http://www.aloris.com |

| Aloris Tool Technology Co. Inc. |

973-772-1201 |

http://www.aloris.com |

| Aloris Tool Technology Co. Inc. |

973-772-1201 |

http://www.aloris.com |

| Alpex Wheel Co. |

201-871-1700 |

http://www.alpexwheel.com |

| Alpex Wheel Co. |

201-871-1700 |

http://www.alpexwheel.com |

| Alpex Wheel Co. |

201-871-1700 |

http://www.alpexwheel.com |

| AMAMCO Tool |

864-877-0919 |

http://www.amamcotool.com |

| AMAMCO Tool |

864-877-0919 |

http://www.amamcotool.com |

| AMAMCO Tool |

864-877-0919 |

http://www.amamcotool.com |

| AMAMCO Tool |

864-877-0919 |

http://www.amamcotool.com |

| AMAMCO Tool |

864-877-0919 |

http://www.amamcotool.com |

| AMAMCO Tool |

864-877-0919 |

http://www.amamcotool.com |

| AMAMCO Tool |

864-877-0919 |

http://www.amamcotool.com |

| AMAMCO Tool |

864-877-0919 |

http://www.amamcotool.com |

| American Carbide Tool Co. |

330-455-2009 |

http://www.americancarbidetool.com |

| American Carbide Tool Co. |

330-455-2009 |

http://www.americancarbidetool.com |

| American Carbide Tool Co. |

330-455-2009 |

http://www.americancarbidetool.com |

| American Carbide Tool Co. |

330-455-2009 |

http://www.americancarbidetool.com |

| American Natl. Carbide |

281-351-7165 |

http://www.anconline.com |

| American Weldquip Inc. |

330-239-0317 |

http://www.weldquip.com |

| Anchor Abrasives Co. |

708-444-4300 |

http://www.anchorabrasives.com |

| AP&T North America Inc. |

704-292-2900 |

http://www.aptgroup.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARCH Cutting Tools |

888-390-2050 |

http://www.ARCHcuttingtools.com |

| ARNO Werkzeuge USA |

815-943-4426 |

http://www.arnousa.com |

| ARNO Werkzeuge USA |

815-943-4426 |

http://www.arnousa.com |

| ARNO Werkzeuge USA |

815-943-4426 |

http://www.arnousa.com |

| ARNO Werkzeuge USA |

815-943-4426 |

http://www.arnousa.com |

| ARNO Werkzeuge USA |

815-943-4426 |

http://www.arnousa.com |

| ARNO Werkzeuge USA |

815-943-4426 |

http://www.arnousa.com |

| ARNO Werkzeuge USA |

815-943-4426 |

http://www.arnousa.com |

| Arnold Fastening Systems Inc. |

248-997-2000 |

https://www.arnold-fastening.com |

| ATA Tools Inc. |

330-849-2647 |

http://www.atagroup.co |

| ATA Tools Inc. |

330-849-2647 |

http://www.atagroup.co |

| ATA Tools Inc. |

330-849-2647 |

http://www.atagroup.co |

| atto Abrasives |

353-51-562-700 |

https://attoabrasives.com/ |

| atto Abrasives |

353-51-562-700 |

https://attoabrasives.com/ |

| Aurora Scientific Corp. |

604-207-0633 |

http://www.aurorascicorp.com |

| Aven Inc. |

734-973-0099 |

http://www.aveninc.com |

| Bahco Bandsaw Blades |

800-446-7404 |

http://www.snaponindustrialbrands.com |

| Barcor Inc. |

847-940-0750 |

http://www.barcorgages.com |

| Behringer Saws Inc. |

888-234-7464 |

http://www.behringersaws.com |

| Beijing Worldia Diamond Tools Co. Ltd. |

+86-10-58411388 ext.8338 |

http://www.worldia-tools.com |

| Beijing Worldia Diamond Tools Co. Ltd. |

+86-10-58411388 ext.8338 |

http://www.worldia-tools.com |

| Beijing Worldia Diamond Tools Co. Ltd. |

+86-10-58411388 ext.8338 |

http://www.worldia-tools.com |

| Beijing Worldia Diamond Tools Co. Ltd. |

+86-10-58411388 ext.8338 |

http://www.worldia-tools.com |

| Beijing Worldia Diamond Tools Co. Ltd. |

+86-10-58411388 ext.8338 |

http://www.worldia-tools.com |

| Beijing Worldia Diamond Tools Co. Ltd. |

+86-10-58411388 ext.8338 |

http://www.worldia-tools.com |

| Belmont Equip. & Technologies |

248-588-7011 |

http://www.belmont4edm.com |

| Belmont Equip. & Technologies |

248-588-7011 |

http://www.belmont4edm.com |

| Besly Cutting Tools |

815-389-2231 |

http://www.besly.com |

| Besly Cutting Tools |

815-389-2231 |

http://www.besly.com |

| Besly Cutting Tools |

815-389-2231 |

http://www.besly.com |

| Besly Cutting Tools |

815-389-2231 |

http://www.besly.com |

| Besly Cutting Tools |

815-389-2231 |

http://www.besly.com |

| Besly Cutting Tools |

815-389-2231 |

http://www.besly.com |

| Best Carbide Cutting Tools LLC |

310-464-8050 |

http://www.bestcarbide.com |

| Best Carbide Cutting Tools LLC |

310-464-8050 |

http://www.bestcarbide.com |

| BIG DAISHOWA Inc. |

224-770-2999 |

https://www.bigdaishowa.com/en |

| BIG DAISHOWA Inc. |

224-770-2999 |

https://www.bigdaishowa.com/en |

| BIG DAISHOWA Inc. |

224-770-2999 |

https://www.bigdaishowa.com/en |

| BIG DAISHOWA Inc. |

224-770-2999 |

https://www.bigdaishowa.com/en |

| BIG DAISHOWA Inc. |

224-770-2999 |

https://www.bigdaishowa.com/en |

| Bodle Diamond Industries |

800-607-3798 |

|

| Bokum Tool Co. |

248-585-0222 |

http://www.bokumtoolco.com |

| Bokum Tool Co. |

248-585-0222 |

http://www.bokumtoolco.com |

| Bokum Tool Co. |

248-585-0222 |

http://www.bokumtoolco.com |

| Bokum Tool Co. |

248-585-0222 |

http://www.bokumtoolco.com |

| Bokum Tool Co. |

248-585-0222 |

http://www.bokumtoolco.com |

| Bosch Tools |

877-267-2499 |

http://www.boschtools.com/ |

| Botek USA Inc. |

630-893-5300 |

http://www.botekusa.com |

| Botek USA Inc. |

630-893-5300 |

http://www.botekusa.com |

| Botek USA Inc. |

630-893-5300 |

http://www.botekusa.com |

| Briney Tooling Systems |

989-269-9558 |

http://www.brineytooling.com |

| BTA Heller |

248-597-0346 |

http://www.btahellerinc.com |

| BTA Heller |

248-597-0346 |

http://www.btahellerinc.com |

| BTA Heller |

248-597-0346 |

http://www.btahellerinc.com |

| BTA Heller |

248-597-0346 |

http://www.btahellerinc.com |

| Calculated Industries |

775-885-4900 |

http://www.calculated.com |

| Carbide Products Inc. |

877-863-2340 |

http://www.carbidepros.com |

| Carbide Products Inc. |

877-863-2340 |

http://www.carbidepros.com |

| Carbide Products Inc. |

877-863-2340 |

http://www.carbidepros.com |

| Carbide Products Inc. |

877-863-2340 |

http://www.carbidepros.com |

| Carbide Products Inc. |

877-863-2340 |

http://www.carbidepros.com |

| Carbide Tool Services Inc. |

763-421-2210 |

http://www.carbidetool.com |

| Carbide Tool Services Inc. |

763-421-2210 |

http://www.carbidetool.com |

| Carbide Tools Mfg. Inc. |

262-251-0099 |

http://www.carbidetools.com |

| Carbide Tools Mfg. Inc. |

262-251-0099 |

http://www.carbidetools.com |

| Carbide Tools Mfg. Inc. |

262-251-0099 |

http://www.carbidetools.com |

| Carbide Tools Mfg. Inc. |

262-251-0099 |

http://www.carbidetools.com |

| Carbide Tools Mfg. Inc. |

262-251-0099 |

http://www.carbidetools.com |

| Carbide Tools Mfg. Inc. |

262-251-0099 |

http://www.carbidetools.com |

| carbide.ca |

416-895-4769 |

http://www.carbide.ca |

| carbide.ca |

416-895-4769 |

http://www.carbide.ca |

| carbide.ca |

416-895-4769 |

http://www.carbide.ca |

| carbide.ca |

416-895-4769 |

http://www.carbide.ca |

| carbide.ca |

416-895-4769 |

http://www.carbide.ca |

| carbide.ca |

416-895-4769 |

http://www.carbide.ca |

| carbide.ca |

416-895-4769 |

http://www.carbide.ca |

| Carmex Precision Tools |

262-628-5030 |

http://www.carmexusa.com |

| Carmex Precision Tools |

262-628-5030 |

http://www.carmexusa.com |

| Carmex Precision Tools |

262-628-5030 |

http://www.carmexusa.com |

| Castlebar Corporation |

330-451-6511 |

http://www.castlebar.us |

| Castlebar Corporation |

330-451-6511 |

http://www.castlebar.us |

| Castlebar Corporation |

330-451-6511 |

http://www.castlebar.us |

| Castlebar Corporation |

330-451-6511 |

http://www.castlebar.us |

| Castlebar Corporation |

330-451-6511 |

http://www.castlebar.us |

| CDP Diamond Products Inc. |

800-521-0638 |

http://www.cdpdiamond.com |

| CDP Diamond Products Inc. |

800-521-0638 |

http://www.cdpdiamond.com |

| CDP Diamond Products Inc. |

800-521-0638 |

http://www.cdpdiamond.com |

| CDP Diamond Products Inc. |

800-521-0638 |

http://www.cdpdiamond.com |

| CDP Diamond Products Inc. |

800-521-0638 |

http://www.cdpdiamond.com |

| CDP Diamond Products Inc. |

800-521-0638 |

http://www.cdpdiamond.com |

| CEJN Industrial Corp. |

847-263-7200 |

http://www.cejn.us |

| Century Machine Inc. |

641-866-6748 |

http://www.centurymachine.com |

| Century Tool & Design Inc. |

860-621-6748 |

http://www.centtool.com |

| Century Tool & Design Inc. |

860-621-6748 |

http://www.centtool.com |

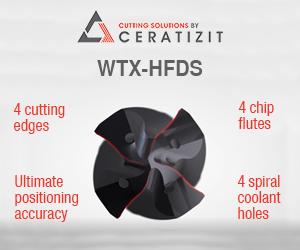

| Ceratizit USA Inc. |

800-783-2280 |

https://cuttingtools.ceratizit.com/us/en.html |

| Ceratizit USA Inc. |

800-783-2280 |

https://cuttingtools.ceratizit.com/us/en.html |

| Ceratizit USA Inc. |

800-783-2280 |

https://cuttingtools.ceratizit.com/us/en.html |

| Ceratizit USA Inc. |

800-783-2280 |

https://cuttingtools.ceratizit.com/us/en.html |

| Ceratizit USA Inc. |

800-783-2280 |

https://cuttingtools.ceratizit.com/us/en.html |

| Ceratizit USA Inc. |

800-783-2280 |

https://cuttingtools.ceratizit.com/us/en.html |

| Ceratizit USA Inc. |

800-783-2280 |

https://cuttingtools.ceratizit.com/us/en.html |

| Ceratizit USA Inc. |

800-783-2280 |

https://cuttingtools.ceratizit.com/us/en.html |

| Ceratizit USA Inc. |

800-783-2280 |

https://cuttingtools.ceratizit.com/us/en.html |

| CGW-Camel Grinding Wheels |

847-647-5994 |

http://www.cgwcamel.com |

| CGW-Camel Grinding Wheels |

847-647-5994 |

http://www.cgwcamel.com |

| Champion Cutting Tool Corp. |

516-536-8200 |

http://www.championcuttingtool.com |

| Champion Cutting Tool Corp. |

516-536-8200 |

http://www.championcuttingtool.com |

| Champion Cutting Tool Corp. |

516-536-8200 |

http://www.championcuttingtool.com |

| Chardon Tool |

440-286-6440 |

http://www.chardontool.com |

| Chardon Tool |

440-286-6440 |

http://www.chardontool.com |

| Cheboygan Tap & Tool Co. |

231-627-3133 |

http://www.cheboygantap.com |

| Cheboygan Tap & Tool Co. |

231-627-3133 |

http://www.cheboygantap.com |

| Cheboygan Tap & Tool Co. |

231-627-3133 |

http://www.cheboygantap.com |

| Chevin Tools Inc. |

847-690-1278 |

http://www.chevintools.com |

| Chicago Quadrill Co. |

847-824-4196 |

|

| Chicago Quadrill Co. |

847-824-4196 |

|

| Chips Tool Repair |

763-323-4080 |

http://www.chipstoolrepair.com |

| Chips Tool Repair |

763-323-4080 |

http://www.chipstoolrepair.com |

| Chips Tool Repair |

763-323-4080 |

http://www.chipstoolrepair.com |

| Chips Tool Repair |

763-323-4080 |

http://www.chipstoolrepair.com |

| Chips Tool Repair |

763-323-4080 |

http://www.chipstoolrepair.com |

| CJT Koolcarb Inc. |

630-690-5933 |

http://www.cjtkoolcarb.com |

| CJT Koolcarb Inc. |

630-690-5933 |

http://www.cjtkoolcarb.com |

| CJT Koolcarb Inc. |

630-690-5933 |

http://www.cjtkoolcarb.com |

| CJWinter Machine |

585-429-5000 |

http://www.cjwinter.com |

| CJWinter Machine |

585-429-5000 |

http://www.cjwinter.com |

| Clausing Industrial Inc. |

269-345-7155 |

http://www.clausing-industrial.com |

| Cline Tool |

641-792-7086 |

http://www.clinetool.com |

| Cline Tool |

641-792-7086 |

http://www.clinetool.com |

| Cline Tool |

641-792-7086 |

http://www.clinetool.com |

| CNC Broach Tool |

877-248-1631 |

https://www.cncbroachtools.com |

| Cobra Carbide |

951-280-4700 |

https://cobracarbide.wordpress.com |

| Cobra Carbide |

951-280-4700 |

https://cobracarbide.wordpress.com |

| Cobra Carbide |

951-280-4700 |

https://cobracarbide.wordpress.com |

| Cobra Carbide |

951-280-4700 |

https://cobracarbide.wordpress.com |

| Cobra Carbide |

951-280-4700 |

https://cobracarbide.wordpress.com |

| Cobra Carbide |

951-280-4700 |

https://cobracarbide.wordpress.com |

| Cobra Carbide |

951-280-4700 |

https://cobracarbide.wordpress.com |

| Cobra Carbide |

951-280-4700 |

https://cobracarbide.wordpress.com |

| Cobra Carbide |

951-280-4700 |

https://cobracarbide.wordpress.com |

| Cogsdill Tool Products Inc. |

803-438-4000 |

http://www.cogsdill.com |

| Cogsdill Tool Products Inc. |

803-438-4000 |

http://www.cogsdill.com |

| Cogsdill Tool Products Inc. |

803-438-4000 |

http://www.cogsdill.com |

| Cogsdill Tool Products Inc. |

803-438-4000 |

http://www.cogsdill.com |

| Cogsdill Tool Products Inc. |

803-438-4000 |

http://www.cogsdill.com |

| Cogsdill Tool Products Inc. |

803-438-4000 |

http://www.cogsdill.com |

| Cogsdill Tool Products Inc. |

803-438-4000 |

http://www.cogsdill.com |

| Coherent Inc. |

408-764-4983 |

http://www.coherent.com |

| Coherent Inc. |

408-764-4983 |

http://www.coherent.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Cole Family of Companies |

586-757-8700 |

http://www.colecarbide.com |

| Colonial Tool Group Inc. |

519-253-2461 |

http://www.colonialtool.com |

| Colonial Tool Group Inc. |

519-253-2461 |

http://www.colonialtool.com |

| Colonial Tool Group Inc. |

519-253-2461 |

http://www.colonialtool.com |

| Columbia Marking Tools |

586-949-8400 |

http://www.columbiamt.com |

| Columbia Marking Tools |

586-949-8400 |

http://www.columbiamt.com |

| Command Tooling Systems/EWS Group |

763-576-6910 |

http://www.commandtool.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Complete Tool Grinding Inc. |

763-571-4242 |

http://www.completetoolgrinding.com |

| Conicity Technologies LLC |

724-537-3555 |

http://www.conicity.com |

| Conicity Technologies LLC |

724-537-3555 |

http://www.conicity.com |

| Conicity Technologies LLC |

724-537-3555 |

http://www.conicity.com |

| Continental Pipe & Tube Cut-Off Machines |

630-543-7170 |

http://www.continentalcutoff.com |

| Contour360° |

207-625-4000 |

http://www.contour360.com |

| Contour360° |

207-625-4000 |

http://www.contour360.com |

| Contour360° |

207-625-4000 |

http://www.contour360.com |

| Contour360° |

207-625-4000 |

http://www.contour360.com |

| Contour360° |

207-625-4000 |

http://www.contour360.com |

| Contour360° |

207-625-4000 |

http://www.contour360.com |

| Contour360° |

207-625-4000 |

http://www.contour360.com |

| Controx Inc. |

937-325-2888 |

http://www.controx.com |

| Cosen Saws USA |

704-943-1030 |

http://www.cosensaws.com |

| Craftsman Industries Inc. |

702-566-5808 |

http://www.craftsmanindustries.com |

| Craig Tools Inc |

310-414-5707 |

http://www.craigtools.com |

| Craig Tools Inc |

310-414-5707 |

http://www.craigtools.com |

| Craig Tools Inc |

310-414-5707 |

http://www.craigtools.com |

| Createch Machine and Design |

863-688-0071 |

http://www.createch-design.com |

| Createch Machine and Design |

863-688-0071 |

http://www.createch-design.com |

| Crowley Tool Co. |

615-824-5594 |

https://crowleytool.com |

| Crowley Tool Co. |

615-824-5594 |

https://crowleytool.com |

| Crowley Tool Co. |

615-824-5594 |

https://crowleytool.com |

| Crowley Tool Co. |

615-824-5594 |

https://crowleytool.com |

| Crowley Tool Co. |

615-824-5594 |

https://crowleytool.com |

| Crystallume |

408-653-1700 |

http://www.crystallume.com |

| Crystallume |

408-653-1700 |

http://www.crystallume.com |

| Crystallume |

408-653-1700 |

http://www.crystallume.com |

| Crystallume |

408-653-1700 |

http://www.crystallume.com |

| Custom Cutting Tools |

858-578-1640 |

http://www.customcuttingtools.com |

| Cutting Tool Engineers |

205-733-0100 |

http://www.cuttingtoolengineers.com |

| Cutting Tool Engineers |

205-733-0100 |

http://www.cuttingtoolengineers.com |

| D&C Tool Grinding Inc. |

918-689-9799 |

|

| D&C Tool Grinding Inc. |

918-689-9799 |

|

| D&C Tool Grinding Inc. |

918-689-9799 |

|

| D&C Tool Grinding Inc. |

918-689-9799 |

|

| D&C Tool Grinding Inc. |

918-689-9799 |

|

| D&C Tool Grinding Inc. |

918-689-9799 |

|

| D.C. Morrison Co. |

859-581-7511 |

http://www.dcmorrison.com |

| D.C. Morrison Co. |

859-581-7511 |

http://www.dcmorrison.com |

| Daito USA Inc. |

847-437-6788 |

http://www.daitousa.com |

| Dapra Corp. |

860-242-8539 |

http://www.dapra.com |

| Dapra Corp. |

860-242-8539 |

http://www.dapra.com |

| Dapra Corp. |

860-242-8539 |

http://www.dapra.com |

| Darex |

541-552-1301 |

http://www.darex.com |

| Darex |

541-552-1301 |

http://www.darex.com |

| Datum Point Tool Inc. |

248-588-8588 |

http://www.radstartool.com |

| Datum Point Tool Inc. |

248-588-8588 |

http://www.radstartool.com |

| Datum Point Tool Inc. |

248-588-8588 |

http://www.radstartool.com |

| Datum Point Tool Inc. |

248-588-8588 |

http://www.radstartool.com |

| Datum Point Tool Inc. |

248-588-8588 |

http://www.radstartool.com |

| Datum Point Tool Inc. |

248-588-8588 |

http://www.radstartool.com |

| Dedeco Intl. Inc. |

845-887-4840 |

http://www.dedeco.com |

| Dedeco Intl. Inc. |

845-887-4840 |

http://www.dedeco.com |

| Dedeco Intl. Inc. |

845-887-4840 |

http://www.dedeco.com |

| Desmond-Stephan Mfg. Co. |

937-653-7181 |

http://www.desmond-stephan.com |

| Destiny Tool |

408-988-8898 |

http://www.destinytool.com |

| Diamond Alternatives LLC |

734-755-1505 |

http://www.diamondalternatives.net |

| Diamond Saw Works Inc. |

716-496-7417 |

http://www.diamondsaw.com |

| Diamond Wheel Inc. |

952-939-8922 |

http://www.diamondwheelinc.com |

| Dianamic Abrasive Products Inc. |

248-280-1185 |

http://www.dianamic.com |

| Diversified Machine Systems |

719-226-5066 |

https://dmscncrouters.com |

| Dormer Pramet |

800-877-3745 |

http://www.dormerpramet.com |

| Dormer Pramet |

800-877-3745 |

http://www.dormerpramet.com |

| Dormer Pramet |

800-877-3745 |

http://www.dormerpramet.com |

| Dormer Pramet |

800-877-3745 |

http://www.dormerpramet.com |

| Dormer Pramet |

800-877-3745 |

http://www.dormerpramet.com |

| Dormer Pramet |

800-877-3745 |

http://www.dormerpramet.com |

| Dormer Pramet |

800-877-3745 |

http://www.dormerpramet.com |

| Drillco Cutting Tools |

225-272-8251 |

http://www.drillco-inc.com |

| Drillco Cutting Tools |

225-272-8251 |

http://www.drillco-inc.com |

| Drillco Cutting Tools |

225-272-8251 |

http://www.drillco-inc.com |

| Drillco Cutting Tools |

225-272-8251 |

http://www.drillco-inc.com |

| Drillco Cutting Tools |

225-272-8251 |

http://www.drillco-inc.com |

| Drillco Cutting Tools |

225-272-8251 |

http://www.drillco-inc.com |

| Dunham Tool Co. |

712-542-1908 |

http://www.dunhamtool.com |

| Dura-Mill Inc. |

518-899-2255 |

http://www.duramill.com |

| E-Z Burr Tool Co. Inc. |

734-744-4500 |

http://www.ezburr.com |

| E-Z Burr Tool Co. Inc. |

734-744-4500 |

http://www.ezburr.com |

| E-Z Burr Tool Co. Inc. |

734-744-4500 |

http://www.ezburr.com |

| E.C. Kitzel & Sons Inc. |

216-267-6850 |

http://www.kitzel.com |

| E.C. Kitzel & Sons Inc. |

216-267-6850 |

http://www.kitzel.com |

| E.C. Kitzel & Sons Inc. |

216-267-6850 |

http://www.kitzel.com |

| E.P. Heller Co. |

973-377-2878 |

http://www.ephco.com |

| E.P. Heller Co. |

973-377-2878 |

http://www.ephco.com |

| E.P. Heller Co. |

973-377-2878 |

http://www.ephco.com |

| E.P. Heller Co. |

973-377-2878 |

http://www.ephco.com |

| E.P. Heller Co. |

973-377-2878 |

http://www.ephco.com |

| E.P. Heller Co. |

973-377-2878 |

http://www.ephco.com |

| E.P. Heller Co. |

973-377-2878 |

http://www.ephco.com |

| Eagle Superabrasives Inc. |

828-261-7281 |

http://www.eaglesuperabrasives.com |

| Ecoroll Corp. Tool Technology |

513-248-4700 |

http://www.ecoroll.com |

| Ecoroll Corp. Tool Technology |

513-248-4700 |

http://www.ecoroll.com |

| EDGE Deephole Drilling Tools and Systems |

281-807-3131 |

http://www.edgedeephole.com |

| EDGE Deephole Drilling Tools and Systems |

281-807-3131 |

http://www.edgedeephole.com |

| EDGE Deephole Drilling Tools and Systems |

281-807-3131 |

http://www.edgedeephole.com |

| EDGE Deephole Drilling Tools and Systems |

281-807-3131 |

http://www.edgedeephole.com |

| EDGE Deephole Drilling Tools and Systems |

281-807-3131 |

http://www.edgedeephole.com |

| EDGE Deephole Drilling Tools and Systems |

281-807-3131 |

http://www.edgedeephole.com |

| Edge Technology |

636-488-5566 |

http://www.et-carbide.com |

| Edge Technology |

636-488-5566 |

http://www.et-carbide.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| EHWA General Tool Inc. |

844-EHWA-USA |

http://www.ehwadiamondusa.com |

| Element Six US Corp. |

281-364-8080 |

http://www.e6.com |

| Ellsworth Cutting Tools Ltd. |

586-598-6040 |

http://www.ellsworthtoolsusa.com |

| Ellsworth Cutting Tools Ltd. |

586-598-6040 |

http://www.ellsworthtoolsusa.com |

| Ellsworth Cutting Tools Ltd. |

586-598-6040 |

http://www.ellsworthtoolsusa.com |

| Ellsworth Cutting Tools Ltd. |

586-598-6040 |

http://www.ellsworthtoolsusa.com |

| Ellsworth Cutting Tools Ltd. |

586-598-6040 |

http://www.ellsworthtoolsusa.com |

| Ellsworth Cutting Tools Ltd. |

586-598-6040 |

http://www.ellsworthtoolsusa.com |

| Ellsworth Cutting Tools Ltd. |

586-598-6040 |

http://www.ellsworthtoolsusa.com |

| Eltool Corp. |

513-723-1772 |

http://www.eltool.com |

| Eltool Corp. |

513-723-1772 |

http://www.eltool.com |

| EMUGE-FRANKEN USA |

508-595-3600 |

http://www.emuge.com |

| EMUGE-FRANKEN USA |

508-595-3600 |

http://www.emuge.com |

| EMUGE-FRANKEN USA |

508-595-3600 |

http://www.emuge.com |

| EMUGE-FRANKEN USA |

508-595-3600 |

http://www.emuge.com |

| EMUGE-FRANKEN USA |

508-595-3600 |

http://www.emuge.com |

| EMUGE-FRANKEN USA |

508-595-3600 |

http://www.emuge.com |

| EMUGE-FRANKEN USA |

508-595-3600 |

http://www.emuge.com |

| Engis Corp. |

847-808-9400 |

https://www.engis.com |

| Enhanced Pressed Materials LLC |

814-594-5900 |

|

| Enhanced Pressed Materials LLC |

814-594-5900 |

|

| Enhanced Pressed Materials LLC |

814-594-5900 |

|

| Enhanced Pressed Materials LLC |

814-594-5900 |

|

| F&D Tool Co. |

413-283-8321 |

http://www.fdtool.com |

| F&D Tool Co. |

413-283-8321 |

http://www.fdtool.com |

| F&D Tool Co. |

413-283-8321 |

http://www.fdtool.com |

| F&D Tool Co. |

413-283-8321 |

http://www.fdtool.com |

| Fairlane Products |

586-294-6100 |

http://www.fairlaneproducts.com |

| Fersco Saws |

601-922-5367 |

http://www.ferscosaws.com |

| Firth Brown Tools Inc. |

519-621-2610 |

http://www.firthbrown.com |

| Firth Brown Tools Inc. |

519-621-2610 |

http://www.firthbrown.com |

| Fischer Special Tooling |

440-951-8411 |

http://www.fischerspecialtooling.com |

| Fischer Special Tooling |

440-951-8411 |

http://www.fischerspecialtooling.com |

| Fischer Special Tooling |

440-951-8411 |

http://www.fischerspecialtooling.com |

| Fitz-Rite Products |

248-689-7143 |

http://www.fitzrite.com |

| Fitz-Rite Products |

248-689-7143 |

http://www.fitzrite.com |

| Fives Giddings & Lewis |

920-921-9400 |

http://metal-cutting-composites.fivesgroup.com/ |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp. (CITCO Tools) |

440-709-0700 |

https://www.fivesgroup.com |

| Fives Landis Corp.-Gardner Abrasives |

815-389-2251 |

http://abrasives-cutting-tools.fivesgroup.com/ |

| Flex Machine Tools |

800-837-2503 |

https://flexmachinetools.com |

| Flex-E-On Inc. |

330-928-4496 |

http://www.ahd-flex-e-on.com |

| FOBA Laser Marking & Engraving (Alltec GmbH) |

630-694-3243 |

http://www.fobalaser.com |

| Fullerton Tool Co. |

989-799-4550 |

http://www.fullertontool.com |

| Fullerton Tool Co. |

989-799-4550 |

http://www.fullertontool.com |

| Fullerton Tool Co. |

989-799-4550 |

http://www.fullertontool.com |

| Fullerton Tool Co. |

989-799-4550 |

http://www.fullertontool.com |

| Funik Ultrahard Materials (US) Inc. |

626-538-4930 |

http://www.funik.com |

| Gaylee Saws |

216-521-8567 |

http://www.gayleesaws.com |

| Gaylee Saws |

216-521-8567 |

http://www.gayleesaws.com |

| Gaylee Saws |

216-521-8567 |

http://www.gayleesaws.com |

| Gaylee Saws |

216-521-8567 |

http://www.gayleesaws.com |

| Genesee Mfg. Co. Inc. |

585-266-3201 |

http://www.geneseemfg.com |

| Genesee Mfg. Co. Inc. |

585-266-3201 |

http://www.geneseemfg.com |

| Genesee Mfg. Co. Inc. |

585-266-3201 |

http://www.geneseemfg.com |

| Genesee Mfg. Co. Inc. |

585-266-3201 |

http://www.geneseemfg.com |

| Genesee Mfg. Co. Inc. |

585-266-3201 |

http://www.geneseemfg.com |

| Genesee Mfg. Co. Inc. |

585-266-3201 |

http://www.geneseemfg.com |

| Genevieve Swiss Industries Inc. |

413-562-4800 |

http://www.genswiss.com |

| Genevieve Swiss Industries Inc. |

413-562-4800 |

http://www.genswiss.com |

| Genevieve Swiss Industries Inc. |

413-562-4800 |

http://www.genswiss.com |

| Genevieve Swiss Industries Inc. |

413-562-4800 |

http://www.genswiss.com |

| Genevieve Swiss Industries Inc. |

413-562-4800 |

http://www.genswiss.com |

| Genevieve Swiss Industries Inc. |

413-562-4800 |

http://www.genswiss.com |

| Genevieve Swiss Industries Inc. |

413-562-4800 |

http://www.genswiss.com |

| Genevieve Swiss Industries Inc. |

413-562-4800 |

http://www.genswiss.com |

| Gerardi USA |

847-515-3234 |

http://www.gerardiusa.com |

| Gladwin Machine Inc. |

989-426-8753 |

http://www.gladwinmachine.com |

| Gladwin Machine Inc. |

989-426-8753 |

http://www.gladwinmachine.com |

| Gladwin Machine Inc. |

989-426-8753 |

http://www.gladwinmachine.com |

| Gladwin Machine Inc. |

989-426-8753 |

http://www.gladwinmachine.com |

| Gleason Corp. |

585-473-1000 |

http://www.gleason.com |

| Gleason Corp. |

585-473-1000 |

http://www.gleason.com |

| Gleason Corp. |

585-473-1000 |

http://www.gleason.com |

| GMauvaisUSA |

413-863-5152 |

http://www.hassay-savage.com |

| GMSi Group Inc. |

508-612-9482 |

http://www.gmsigroup.com |

| Gorilla Mill |

866-888-9600 |

http://www.cgctool.com |

| Gorilla Mill |

866-888-9600 |

http://www.cgctool.com |

| Gorilla Mill |

866-888-9600 |

http://www.cgctool.com |

| Gorilla Mill |

866-888-9600 |

http://www.cgctool.com |

| Govro Nelson Co. |

810-329-4727 |

http://www.govro.com |

| Govro Nelson Co. |

810-329-4727 |

http://www.govro.com |

| Govro Nelson Co. |

810-329-4727 |

http://www.govro.com |

| Grainger |

847-535-1000 |

http://www.grainger.com |

| Grainger |

847-535-1000 |

http://www.grainger.com |

| Grainger |

847-535-1000 |

http://www.grainger.com |

| Great Lakes Custom Tool Mfg. Inc. |

715-582-3884 |

http://www.glct.com |

| Great Lakes Custom Tool Mfg. Inc. |

715-582-3884 |

http://www.glct.com |

| Greenfield Industries - Cleveland |

800-348-2885 |

http://www.gfii.com |

| Greenfield Industries - Cleveland |

800-348-2885 |

http://www.gfii.com |

| Greenfield Industries - Cleveland |

800-348-2885 |

http://www.gfii.com |

| Greenfield Industries - Cleveland |

800-348-2885 |

http://www.gfii.com |

| Greenfield Industries - Cleveland |

800-348-2885 |

http://www.gfii.com |

| Greenfield Industries - Cleveland |

800-348-2885 |

http://www.gfii.com |

| Greenfield Industries - Cleveland |

800-348-2885 |

http://www.gfii.com |

| Greenfield Industries - Cleveland |

800-348-2885 |

http://www.gfii.com |

| Greenleaf Corp. |

814-763-2915 |

http://www.greenleafcorporation.com |

| Greenleaf Corp. |

814-763-2915 |

http://www.greenleafcorporation.com |

| Greenleaf Corp. |

814-763-2915 |

http://www.greenleafcorporation.com |

| Greenleaf Corp. |

814-763-2915 |

http://www.greenleafcorporation.com |

| Greenleaf Corp. |

814-763-2915 |

http://www.greenleafcorporation.com |

| Greenleaf Corp. |

814-763-2915 |

http://www.greenleafcorporation.com |

| Greenleaf Corp. |

814-763-2915 |

http://www.greenleafcorporation.com |

| Greenlee Diamond Tool |

866-451-3316 |

http://www.greenleediamond.com |

| Grizzly Industrial Inc. |

570-546-9663 |

http://www.grizzly.com |

| Grizzly Industrial Inc. |

570-546-9663 |

http://www.grizzly.com |

| Grizzly Industrial Inc. |

570-546-9663 |

http://www.grizzly.com |

| Grizzly Industrial Inc. |

570-546-9663 |

http://www.grizzly.com |

| Grobet File Co. of America |

201-939-6700 |

http://www.grobetusa.com |

| Grobet File Co. of America |

201-939-6700 |

http://www.grobetusa.com |

| Guhring Inc. |

262-784-6730 |

http://www.guhring.com |

| Guhring Inc. |

262-784-6730 |

http://www.guhring.com |

| Guhring Inc. |

262-784-6730 |

http://www.guhring.com |

| Guhring Inc. |

262-784-6730 |

http://www.guhring.com |

| Guhring Inc. |

262-784-6730 |

http://www.guhring.com |

| Guhring Inc. |

262-784-6730 |

http://www.guhring.com |

| Guhring Inc. |

262-784-6730 |

http://www.guhring.com |

| Guhring Inc. |

262-784-6730 |

http://www.guhring.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| GWS Tool Group |

352-343-8311 |

http://www.gwstoolgroup.com |

| Haimer USA LLC |

630-833-1500 |

https://haimer.com/us |

| Hainbuch America Corp. |

414-358-9550 |

http://www.hainbuchamerica.com |

| Halifax Rack & Screw |

513-449-4296 |

http://www.halifaxrs.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hannibal Carbide Tool Inc. |

573-221-2775 |

http://www.hannibalcarbide.com |

| Hartland Cutting Tools Inc. |

847-639-9400 |

http://www.hartlandtool.com |

| Hartland Cutting Tools Inc. |

847-639-9400 |

http://www.hartlandtool.com |

| Hartland Cutting Tools Inc. |

847-639-9400 |

http://www.hartlandtool.com |

| Hartland Cutting Tools Inc. |

847-639-9400 |

http://www.hartlandtool.com |

| Hartland Cutting Tools Inc. |

847-639-9400 |

http://www.hartlandtool.com |

| Harvey Performance Co. |

844-393-8665 |

http://www.harveyperformance.com |

| Harvey Performance Co. |

844-393-8665 |

http://www.harveyperformance.com |

| Harvey Performance Co. |

844-393-8665 |

http://www.harveyperformance.com |

| Harvey Performance Co. |

844-393-8665 |

http://www.harveyperformance.com |

| Harvey Performance Co. |

844-393-8665 |

http://www.harveyperformance.com |

| Harvey Performance Co. |

844-393-8665 |

http://www.harveyperformance.com |

| Harvey Performance Co. |

844-393-8665 |

http://www.harveyperformance.com |

| Hermann Schmidt Precision Workholding |

860-289-3347 |

http://www.hschmidt.com |

| Hermes Abrasives Ltd. |

757-486-6623 |

http://www.hermesabrasives.com |

| HEULE Tool Corp. |

513-860-9900 |

http://www.heuletool.com |

| HEULE Tool Corp. |

513-860-9900 |

http://www.heuletool.com |

| HEULE Tool Corp. |

513-860-9900 |

http://www.heuletool.com |

| HEULE Tool Corp. |

513-860-9900 |

http://www.heuletool.com |

| HEULE Tool Corp. |

513-860-9900 |

http://www.heuletool.com |

| Hexagon Mfg. Intelligence |

401-886-2000 |

http://www.hexagonmetrology.us |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| HORN USA Inc. |

615-771-4100 |

http://www.hornusa.com |

| Hyde Group |

508-764-4344 |

http://www.hydetools.com |

| Hyde Group |

508-764-4344 |

http://www.hydetools.com |

| Hydra-Lock Corp. |

586-783-5007 |

http://www.hydralock.com |

| Hydra-Lock Corp. |

586-783-5007 |

http://www.hydralock.com |

| Hyperion Materials & Technologies |

614-438-2300 |

https://www.hyperionmt.com/ |

| Hypneumat Inc. |

414-423-7400 |

http://www.hypneumat.com |

| Hypneumat Inc. |

414-423-7400 |

http://www.hypneumat.com |

| ICO Surface Coatings Inc. |

330-225-3939 |

http://www.icosurfacecoatings.com |

| ICO Surface Coatings Inc. |

330-225-3939 |

http://www.icosurfacecoatings.com |

| ICO Surface Coatings Inc. |

330-225-3939 |

http://www.icosurfacecoatings.com |

| IMCO Carbide Tool Inc. |

800-765-4626 |

http://www.imcousa.com |

| IMCO Carbide Tool Inc. |

800-765-4626 |

http://www.imcousa.com |

| IMCO Carbide Tool Inc. |

800-765-4626 |

http://www.imcousa.com |

| IMCO Carbide Tool Inc. |

800-765-4626 |

http://www.imcousa.com |

| IMCO Carbide Tool Inc. |

800-765-4626 |

http://www.imcousa.com |

| IMCO Carbide Tool Inc. |

800-765-4626 |

http://www.imcousa.com |

| Indexa-V Drill Products |

877-645-5782 |

http://www.indexa-v.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Ingersoll Cutting Tools |

815-387-6600 |

http://www.ingersoll-imc.com |

| Inovatools USA LLC |

810-444-8745 |

http://www.inovatools.eu |

| International Drill Guide Inc. |

864-225-2214 |

http://www.gundrill.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| Iscar USA |

817-258-3200 |

http://www.iscarmetals.com |

| ITI Tooling Co. Inc. |

201-934-6333 |

http://www.ititooling.com |

| ITR Inc. |

262-549-9414 |

http://www.itrincwi.com |

| ITR Inc. |

262-549-9414 |

http://www.itrincwi.com |

| J&M Diamond Tool Inc. |

401-431-2220 |

http://www.diamondtool.com |

| J&M Diamond Tool Inc. |

401-431-2220 |

http://www.diamondtool.com |

| J&M Diamond Tool Inc. |

401-431-2220 |

http://www.diamondtool.com |

| J&M Diamond Tool Inc. |

401-431-2220 |

http://www.diamondtool.com |

| J.F. Berns Co. |

513-851-4600 |

http://www.jfberns.com |

| J.F. Berns Inc. |

513-851-4600 |

http://www.jfberns.com |

| James Engineering |

303-444-6787 |

https://www.james-engineering.com |

| Japan USA Precision Tools |

562-883-0310 |

https://japanprecision.us |

| Japan USA Precision Tools |

562-883-0310 |

https://japanprecision.us |

| Jarvis Cutting Tools |

603-332-9000 |

http://www.jarviscuttingtools.com |

| Jarvis Cutting Tools |

603-332-9000 |

http://www.jarviscuttingtools.com |

| Jarvis Cutting Tools |

603-332-9000 |

http://www.jarviscuttingtools.com |

| Jarvis Cutting Tools |

603-332-9000 |

http://www.jarviscuttingtools.com |

| JM Sales |

248-879-5984 |

http://www.jmsales-usa.com |

| JM Sales |

248-879-5984 |

http://www.jmsales-usa.com |

| JM Sales |

248-879-5984 |

http://www.jmsales-usa.com |

| JM Sales |

248-879-5984 |

http://www.jmsales-usa.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Johnson Carbide Products (JCP) LLC |

989-754-7496 |

http://www.johnsoncarbide.com |

| Kanefusa Corp. |

859-283-1450 |

http://www.kanefusa.net |

| Kanefusa Corp. |

859-283-1450 |

http://www.kanefusa.net |

| Kanefusa Corp. |

859-283-1450 |

http://www.kanefusa.net |

| Kasto Inc. |

724-325-5600 |

http://www.kasto.com |

| Kays Engineering Inc./DeHoff/Eldorado |

660-886-9929 |

http://www.kays-dehoff.com |

| Kennametal Inc. |

724-539-5000 |

http://www.kennametal.com |

| Kennametal Inc. |

724-539-5000 |

http://www.kennametal.com |

| Kennametal Inc. |

724-539-5000 |

http://www.kennametal.com |

| Kennametal Inc. |

724-539-5000 |

http://www.kennametal.com |

| Kennametal Inc. |

724-539-5000 |

http://www.kennametal.com |

| Kennametal Inc. |

724-539-5000 |

http://www.kennametal.com |

| Kennametal Inc. |

724-539-5000 |

http://www.kennametal.com |

| Kennametal Inc. |

724-539-5000 |

http://www.kennametal.com |

| Kennametal Inc. |

724-539-5000 |

http://www.kennametal.com |

| Kinefac Corp. |

508-754-6891 |

http://kinefac.com |

| Kinefac Corp. |

508-754-6891 |

http://kinefac.com |

| Kitagawa NorthTech Inc. |

847-885-5100 |

http://www.kitagawa.us |

| Kitagawa NorthTech Inc. |

847-885-5100 |

http://www.kitagawa.us |

| Klingelhofer Corp. |

908-232-7200 |

http://www.klingelhofer.com |

| Knight Carbide |

586-598-4888 |

http://www.knightcarbide.com |

| Knight Carbide |

586-598-4888 |

http://www.knightcarbide.com |

| Knight Carbide |

586-598-4888 |

http://www.knightcarbide.com |

| Knight Carbide |

586-598-4888 |

http://www.knightcarbide.com |

| Knight Carbide |

586-598-4888 |

http://www.knightcarbide.com |

| Knight Carbide |

586-598-4888 |

http://www.knightcarbide.com |

| Koma Precision Inc. |

860-627-7059 |

http://www.komaprecision.com |

| Koma Precision Inc. |

860-627-7059 |

http://www.komaprecision.com |

| KOMET of America Inc. |

847-923-8400 |

http://www.komet.com |

| KOMET of America Inc. |

847-923-8400 |

http://www.komet.com |

| KOMET of America Inc. |

847-923-8400 |

http://www.komet.com |

| KOMET of America Inc. |

847-923-8400 |

http://www.komet.com |

| KOMET of America Inc. |

847-923-8400 |

http://www.komet.com |

| Korloy America Inc. |

310-782-3800 |

http://korloy.com/en/main/main.do |

| Korloy America Inc. |

310-782-3800 |

http://korloy.com/en/main/main.do |

| Krebs & Riedel Schleifscheibenfabrik GmbH & Co. KG |

49-5672-1840 |

http://www.krebs-riedel.de |

| Kwik Mark Inc. |

815-363-8268 |

http://www.kwikmark.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera Precision Tools |

800-823-7284 |

http://www.kyoceraprecisiontools.com |

| Kyocera SGS Precision Tools |

330-686-4130 |

https://www.kyocera-sgstool.com/ |

| Kyocera SGS Precision Tools |

330-686-4130 |

https://www.kyocera-sgstool.com/ |

| Kyocera SGS Precision Tools |

330-686-4130 |

https://www.kyocera-sgstool.com/ |

| Kyocera Unimerco Tooling Inc. |

734-944-4433 |

http://www.kyocera-unimerco.us |

| Kyocera Unimerco Tooling Inc. |

734-944-4433 |

http://www.kyocera-unimerco.us |

| Kyocera Unimerco Tooling Inc. |

734-944-4433 |

http://www.kyocera-unimerco.us |

| Kyocera Unimerco Tooling Inc. |

734-944-4433 |

http://www.kyocera-unimerco.us |

| Kyocera Unimerco Tooling Inc. |

734-944-4433 |

http://www.kyocera-unimerco.us |

| Lach Diamond Inc. |

616-698-0101 |

http://www.lach-diamond.com |

| Lach Diamond Inc. |

616-698-0101 |

http://www.lach-diamond.com |

| Lach Diamond Inc. |

616-698-0101 |

http://www.lach-diamond.com |

| Lach Diamond Inc. |

616-698-0101 |

http://www.lach-diamond.com |

| Lach Diamond Inc. |

616-698-0101 |

http://www.lach-diamond.com |

| Lach Diamond Inc. |

616-698-0101 |

http://www.lach-diamond.com |

| Leistritz Advanced Technologies Corp. |

201-934-8262 |

http://www.leistritzcorp.com |

| Leistritz Advanced Technologies Corp. |

201-934-8262 |

http://www.leistritzcorp.com |

| LENOX |

413-525-3961 |

http://www.lenoxtools.com |

| LENOX |

413-525-3961 |

http://www.lenoxtools.com |

| Lexington Cutter, Inc. |

941-739-2726 |

https://lexingtoncutter.com/ |

| Lexington Cutter, Inc. |

941-739-2726 |

https://lexingtoncutter.com/ |

| Lexington Cutter, Inc. |

941-739-2726 |

https://lexingtoncutter.com/ |

| Lexington Cutter, Inc. |

941-739-2726 |

https://lexingtoncutter.com/ |

| Lexington Cutter, Inc. |

941-739-2726 |

https://lexingtoncutter.com/ |

| Lexington Cutter, Inc. |

941-739-2726 |

https://lexingtoncutter.com/ |

| Lexington Cutter, Inc. |

941-739-2726 |

https://lexingtoncutter.com/ |

| Lexington Cutter, Inc. |

941-739-2726 |

https://lexingtoncutter.com/ |

| Link Industries, A Link Group Company |

231-238-9012 |

https://linkcuttingtools.com |

| Link Industries, A Link Group Company |

231-238-9012 |

https://linkcuttingtools.com |

| Link Industries, A Link Group Company |

231-238-9012 |

https://linkcuttingtools.com |

| Link Industries, A Link Group Company |

231-238-9012 |

https://linkcuttingtools.com |

| Link Industries, A Link Group Company |

231-238-9012 |

https://linkcuttingtools.com |

| Link Industries, A Link Group Company |

231-238-9012 |

https://linkcuttingtools.com |

| Lixie Hammers |

401-723-5494 |

http://www.lixiehammers.com |

| Lixie Hammers |

401-723-5494 |

http://www.lixiehammers.com |

| LMC Workholding |

574-735-0225 |

http://www.lmcworkholding.com |

| LMT Onsrud LP |

847-362-1560 |

http://www.onsrud.com |

| LMT Onsrud LP |

847-362-1560 |

http://www.onsrud.com |

| LMT Onsrud LP |

847-362-1560 |

http://www.onsrud.com |

| LMT USA Inc. |

847-693-3270 |

http://www.lmtusa.com |

| LMT USA Inc. |

847-693-3270 |

http://www.lmtusa.com |

| LMT USA Inc. |

847-693-3270 |

http://www.lmtusa.com |

| LMT USA Inc. |

847-693-3270 |

http://www.lmtusa.com |

| LMT USA Inc. |

847-693-3270 |

http://www.lmtusa.com |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Louis Belet SA |

41-32-474-0410 |

http://www.lbsa.ch |

| Lovejoy Tool Co. Inc. |

802-885-2194 |

http://www.lovejoytool.com |

| Lovejoy Tool Co. Inc. |

802-885-2194 |

http://www.lovejoytool.com |

| Lovejoy Tool Co. Inc. |

802-885-2194 |

http://www.lovejoytool.com |

| Lovejoy Tool Co. Inc. |

802-885-2194 |

http://www.lovejoytool.com |

| Lunzer Technologies Inc. |

201-794-2800 |

http://www.lunzer.com |

| Lunzer Technologies Inc. |

201-794-2800 |

http://www.lunzer.com |

| Lunzer Technologies Inc. |

201-794-2800 |

http://www.lunzer.com |

| Lunzer Technologies Inc. |

201-794-2800 |

http://www.lunzer.com |

| Lunzer Technologies Inc. |

201-794-2800 |

http://www.lunzer.com |

| Lunzer Technologies Inc. |

201-794-2800 |

http://www.lunzer.com |

| Lunzer Technologies Inc. |

201-794-2800 |

http://www.lunzer.com |

| Lyndex-Nikken |

847-367-4800 |

https://lyndexnikken.com |

| Lyndex-Nikken |

847-367-4800 |

https://lyndexnikken.com |

| M.A. Ford |

563-391-6220 |

http://www.maford.com |

| M.A. Ford |

563-391-6220 |

http://www.maford.com |

| M.A. Ford |

563-391-6220 |

http://www.maford.com |

| M.A. Ford |

563-391-6220 |

http://www.maford.com |

| M.A. Ford |

563-391-6220 |

http://www.maford.com |

| M.A. Ford |

563-391-6220 |

http://www.maford.com |

| Machine Control Technologies Inc. |

951-808-0973 |

http://www.machinecontroltechnologies.com |

| MachiningCloud |

805-437-4171, x149 |

https://www.machiningcloud.com/ |

| MachiningCloud |

805-437-4171, x149 |

https://www.machiningcloud.com/ |

| Macro Tool & Machine Co. Inc. |

845-223-3824 |

http://www.macrotool.com |

| Magafor USA |

413-863-9052 |

http://www.hassay-savage.com |

| Magafor USA |

413-863-9052 |

http://www.hassay-savage.com |

| Magafor USA |

413-863-9052 |

http://www.hassay-savage.com |

| Magafor USA |

413-863-9052 |

http://www.hassay-savage.com |

| Mapa Tools Pvt. Ltd. |

91-253-238-3740 |

http://www.mapatools.com |

| Mapa Tools Pvt. Ltd. |

91-253-238-3740 |

http://www.mapatools.com |

| Mapa Tools Pvt. Ltd. |

91-253-238-3740 |

http://www.mapatools.com |

| MAPAL Inc. |

810-364-8020 |

https://www.mapal.com/us/ |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Mastercut Tool Corp. |

727-726-5336 |

http://www.mastercuttool.com |

| Max Pro Tools Inc. |

800-456-0931 |

http://www.maxprotools.com |

| Max Pro Tools Inc. |

800-456-0931 |

http://www.maxprotools.com |

| Max Pro Tools Inc. |

800-456-0931 |

http://www.maxprotools.com |

| Max Pro Tools Inc. |

800-456-0931 |

http://www.maxprotools.com |

| MD Tooling |

810-632-4446 |

http://www.mdtooling.com |

| MD Tooling |

810-632-4446 |

http://www.mdtooling.com |

| MD Tooling |

810-632-4446 |

http://www.mdtooling.com |

| Michigan Deburring Tool |

810-227-1000 |

http://www.mideburring.com |

| Michigan Deburring Tool |

810-227-1000 |

http://www.mideburring.com |

| Michigan Deburring Tool |

810-227-1000 |

http://www.mideburring.com |

| Microcut Inc. |

781-582-8090 |

http://www.microcutusa.com |

| Microcut Inc. |

781-582-8090 |

http://www.microcutusa.com |

| Microcut Inc. |

781-582-8090 |

http://www.microcutusa.com |

| Microcut Inc. |

781-582-8090 |

http://www.microcutusa.com |

| Microcut Inc. |

781-582-8090 |

http://www.microcutusa.com |

| Microcut Inc. |

781-582-8090 |

http://www.microcutusa.com |

| Microtap USA Inc. |

248-852-8277 |

http://www.threadtapping.com |

| Microtap USA Inc. |

248-852-8277 |

http://www.threadtapping.com |

| Midwest FlexSystems Inc. |

810-424-0060 |

http://www.midwestflex.com |

| Midwest Industrial Tool Grinding Inc. |

320-455-0535 |

http://www.mitgi.com |

| Midwest Industrial Tool Grinding Inc. |

320-455-0535 |

http://www.mitgi.com |

| Midwest Industrial Tool Grinding Inc. |

320-455-0535 |

http://www.mitgi.com |

| Midwest Industrial Tool Grinding Inc. |

320-455-0535 |

http://www.mitgi.com |

| Midwest Industrial Tool Grinding Inc. |

320-455-0535 |

http://www.mitgi.com |

| Midwest Industrial Tool Grinding Inc. |

320-455-0535 |

http://www.mitgi.com |

| Midwest Industrial Tool Grinding Inc. |

320-455-0535 |

http://www.mitgi.com |

| Midwest Industrial Tool Grinding Inc. |

320-455-0535 |

http://www.mitgi.com |

| Midwest Ohio Tool Co. |

419-294-1987 |

http://www.midwestohio.com |

| Midwest Ohio Tool Co. |

419-294-1987 |

http://www.midwestohio.com |

| Midwest Ohio Tool Co. |

419-294-1987 |

http://www.midwestohio.com |

| Midwest Ohio Tool Co. |

419-294-1987 |

http://www.midwestohio.com |

| Midwest Ohio Tool Co. |

419-294-1987 |

http://www.midwestohio.com |

| Midwest Ohio Tool Co. |

419-294-1987 |

http://www.midwestohio.com |

| Midwest Ohio Tool Co. |

419-294-1987 |

http://www.midwestohio.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Mikron Tool |

203-261-3100 |

http://www.mikrontool.com |

| Millstar |

586-573-9450 |

http://www.millstar.com |

| Millstar |

586-573-9450 |

http://www.millstar.com |

| Millstar |

586-573-9450 |

http://www.millstar.com |

| Milwaukee Tool |

800-SAWDUST |

http://www.milwaukeetool.com |

| Minicut Intl. Inc. |

514-352-6464 |

http://www.minicut.com |

| Minicut Intl. Inc. |

514-352-6464 |

http://www.minicut.com |

| Minicut Intl. Inc. |

514-352-6464 |

http://www.minicut.com |

| Missilelock.com |

414-881-1712 |

http://www.missilelock.com |

| Missilelock.com |

414-881-1712 |

http://www.missilelock.com |

| Missilelock.com |

414-881-1712 |

http://www.missilelock.com |

| Missilelock.com |

414-881-1712 |

http://www.missilelock.com |

| Missouri Carbide Inc. |

417-471-1047 |

http://www.missouricarbide.com |

| Missouri Carbide Inc. |

417-471-1047 |

http://www.missouricarbide.com |

| Missouri Carbide Inc. |

417-471-1047 |

http://www.missouricarbide.com |

| Missouri Carbide Inc. |

417-471-1047 |

http://www.missouricarbide.com |

| Missouri Carbide Inc. |

417-471-1047 |

http://www.missouricarbide.com |

| Mitchell Abrasives |

978-774-1191 |

http://www.mitchellsabrasives.com |

| Mitsubishi Materials U.S.A. Corp. |

714-352-6100 |

http://www.mitsubishicarbide.com |

| Mitsubishi Materials U.S.A. Corp. |

714-352-6100 |

http://www.mitsubishicarbide.com |

| Mitsubishi Materials U.S.A. Corp. |

714-352-6100 |

http://www.mitsubishicarbide.com |

| Mitsubishi Materials U.S.A. Corp. |

714-352-6100 |

http://www.mitsubishicarbide.com |

| Mitsubishi Materials U.S.A. Corp. |

714-352-6100 |

http://www.mitsubishicarbide.com |

| Mitsubishi Materials U.S.A. Corp. |

714-352-6100 |

http://www.mitsubishicarbide.com |

| Mitsubishi Materials U.S.A. Corp. |

714-352-6100 |

http://www.mitsubishicarbide.com |

| Modulbey Gear Cutting Tools |

+90-212-576-1-576 |

https://www.modulbey.com |

| Modulbey Gear Cutting Tools |

+90-212-576-1-576 |

https://www.modulbey.com |

| Modulbey Gear Cutting Tools |

+90-212-576-1-576 |

https://www.modulbey.com |

| Molemab USA Corp |

800-962-2226 |

http://www.molemab.com |

| Monaghan Tooling Group |

937-253-7706 |

http://www.monaghantooling.com |

| Monaghan Tooling Group |

937-253-7706 |

http://www.monaghantooling.com |

| Monaghan Tooling Group |

937-253-7706 |

http://www.monaghantooling.com |

| Monaghan Tooling Group |

937-253-7706 |

http://www.monaghantooling.com |

| Monaghan Tooling Group |

937-253-7706 |

http://www.monaghantooling.com |

| Monaghan Tooling Group |

937-253-7706 |

http://www.monaghantooling.com |

| Monaghan Tooling Group |

937-253-7706 |

http://www.monaghantooling.com |

| Montfort Intl. Industrial Products Ltd. |

418-877-0778 |

https://montfort-international.com |

| Morse Cutting Tools |

800-255-1701 |

https://www.morsecuttingtools.com/ |

| Morse Cutting Tools |

800-255-1701 |

https://www.morsecuttingtools.com/ |

| Morse Cutting Tools |

800-255-1701 |

https://www.morsecuttingtools.com/ |

| Morse Cutting Tools |

800-255-1701 |

https://www.morsecuttingtools.com/ |

| Morse Cutting Tools |

800-255-1701 |

https://www.morsecuttingtools.com/ |

| Morse Cutting Tools |

800-255-1701 |

https://www.morsecuttingtools.com/ |

| Morse Cutting Tools |

800-255-1701 |

https://www.morsecuttingtools.com/ |

| Nachi America Inc. |

888-340-8665 |

http://www.nachiamerica.com |

| Nachi America Inc. |

888-340-8665 |

http://www.nachiamerica.com |

| Nachi America Inc. |

888-340-8665 |

http://www.nachiamerica.com |

| Nachi America Inc. |

888-340-8665 |

http://www.nachiamerica.com |

| Nachi America Inc. |

888-340-8665 |

http://www.nachiamerica.com |

| Nachi America Inc. |

888-340-8665 |

http://www.nachiamerica.com |

| Nanotech Co. Ltd. |

82-43-217-6390 |

http://www.nanoloy.co.kr/en/ |

| Nanotech Co. Ltd. |

82-43-217-6390 |

http://www.nanoloy.co.kr/en/ |

| New England Die Co. Inc. |

203-574-5140 |

http://www.newenglanddie.com |

| New England Die Co. Inc. |

203-574-5140 |

http://www.newenglanddie.com |

| New England Die Co. Inc. |

203-574-5140 |

http://www.newenglanddie.com |

| New Tech Ceramics Inc. |

515-868-0055 |

http://www.newtechceramics.com |